- Dapatkan link

- X

- Aplikasi Lainnya

- Dapatkan link

- X

- Aplikasi Lainnya

This video helps to understand the complexities that go into making a Tesla automobile. Tesla is seeking a software engineer to build user interfaces for our growing internal workforce of production supply chain and design professionals.

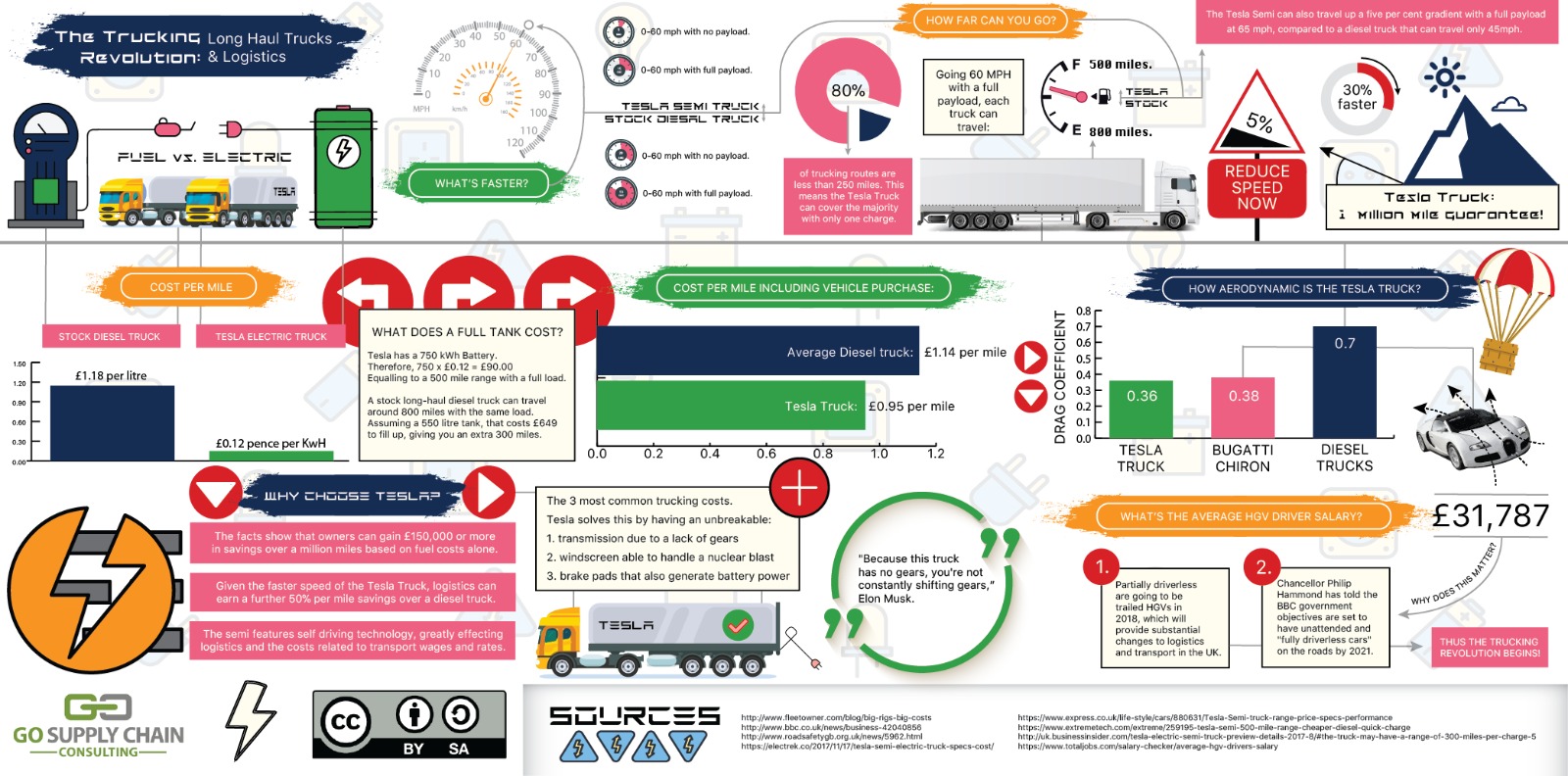

Long-term there is immense opportunity to apply our autonomous technology all built on electric platforms to logistics hubs warehouses intermodal terminals and factories.

Supply chain automation tesla. Tesla may be in a position to disrupt industries well beyond the realm of traditional auto manufacturing. Chinas pollution problem is still severe and widespread so it makes sense for Teslas to capitalize on Chinas desire to incorporate energy-efficient technology. Supply Chain Automation LogisticsStuff If you are selling your home negotiate a lower commission.

Tesla had a great deal of problems in the beginning manufacturing their electric vehicles. Elon Musk has made a cottage industry out of bold pronouncements about the future and hes delivered on some of them before. Teslas supply chain animated.

Building a plant in China will also streamline Teslas supply chain indicative of a larger trend to deliver finished products to consumers as quickly and cheaply as possible. View Supply Chain Automation Internship_Co-Op Fall 2019 _ Teslapdf from BMGT 372 at University of Maryland College Park. The scope includes parts arriving at Teslas network of warehouses then downstream manufacturing facilities.

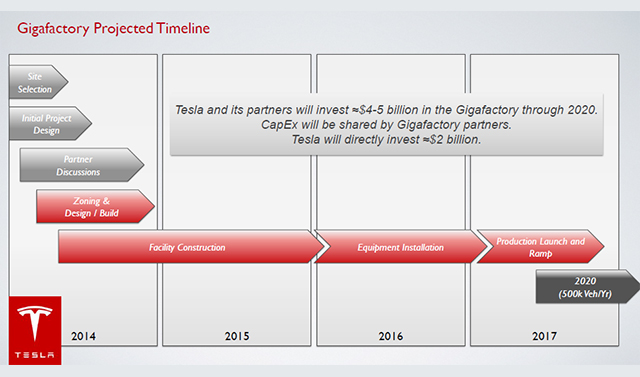

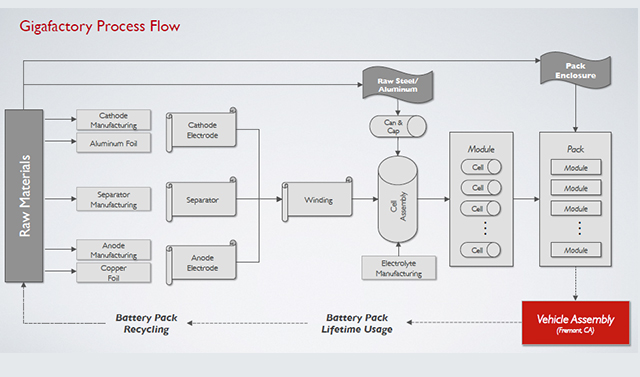

Youd be encouraged to lead teams on initiatives related to warehouse automation facility and material flow design and launch. The Tesla artificial intelligence manufacturing revolution is what sets Tesla apart from several automakers. A big gain in Teslas supply chain will be the Gigafactory which is expected to start production later this year.

But because the company still isnt considered profitable and still hasnt proved skipping the prototype phase in auto manufacturing is feasible or that its supply chain will be able to withstand the companys accelerated growth the future of Teslas automated trucks is uncertain especially in a regulatory world that may leave automated commercial vehicle regulation up to the states. Tesla doesnt always get things right when it comes to their supply chain. Because Tesla does not sell its vehicles via dealerships like other.

7282019 Supply Chain Automation InternshipCo-Op Fall 2019. The company has also been acquiring more land and space in Fremont. If youre not confident that your production and Supply Chain are up to snuff dont overpromise to the consumer.

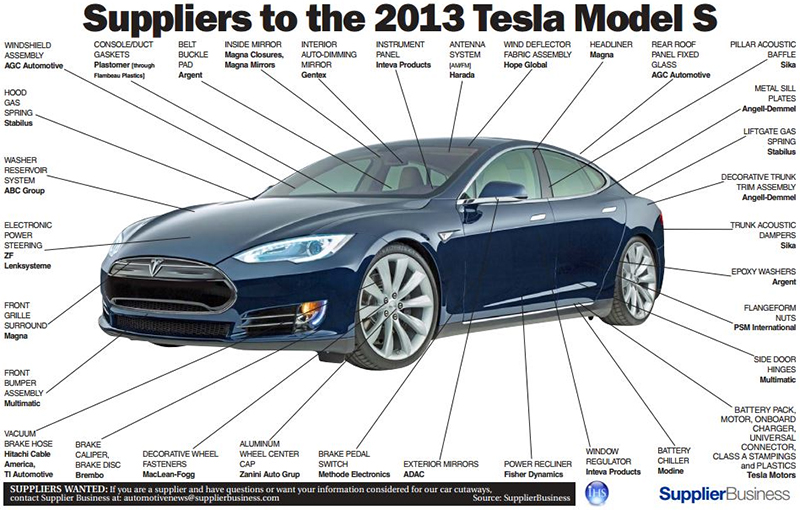

Below is a list of some of the purported key suppliers for Teslas manufacturing production along with the components they supply. As we ready ourselves for simultaneous global new product ramps for CyberTruck Tesla Semi Robotaxi cells and more we need outstanding software that scales with this massive challenge and is. Nevertheless Tesla spent around 16 billion last year to prepare for the Model 3 launch including on people equipment and automation.

The Supply Chain and Ops Automation team is our special. Teslas supply chain and operations teams face increasing challenges as Tesla expands globally and launches new products and programs. Its why hes gained a reputation as a visionary.

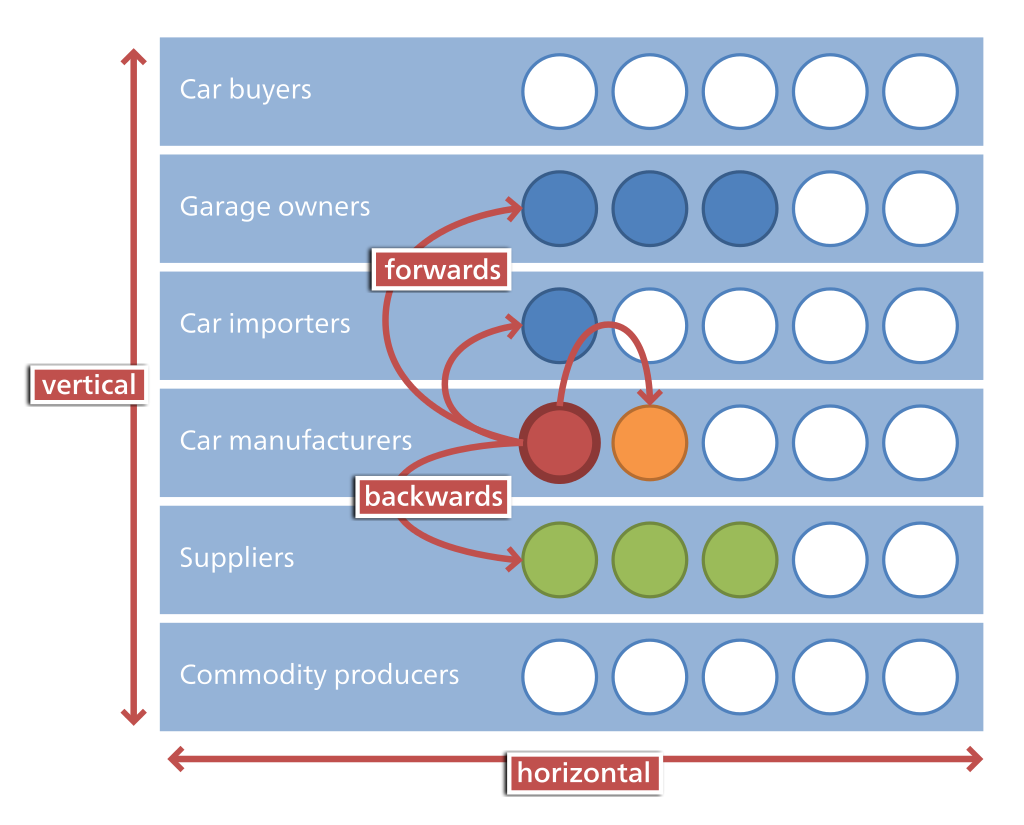

Support supply chain planning operations. Tesla is largely self-contained a significant portion of the Tesla supply chain is company-owned owned and each division within the company supply chain. But what has made Tesla successful is the ability to see what is not working and make it better.

A look at Teslas supply chain. Tesla Motors was founded in 2003 by a group of engineers in Silicon Valley who wanted to prove that electric cars could be better than gasoline-powered cars. With instant torque incredible power and zero emissions Teslas products would be cars without compromise.

Youll gain a deep understanding of capital projects management facility design storage and order fulfillment systems design for distribution networks material flow automation intersection of WCSWES and WMS. By continuously improving their supply chain Tesla has been able to do what many said couldnt be done. As a Planning Intern youd learn how to lead efforts to develop material flow standards and principles for Teslas facilities.

Here are our biggest takeaways for what can be learned from Teslas Supply Chain woes. We are witnessing the most disruptive intersection of supply chain and manufacturing innovation and capital experienced by the auto industry in more than a century. The Gigafactory is the machine that builds machines.

Tesla S Gigafactory Strategy For Executives

Tesla S Revolutionary Supply Chain Supply Chain 24 7

Tesla S Gigafactory Supply Chain Vertical Integration Supply Chain 24 7

The Tesla Semi And The Trucking Revolution Long Haul Trucks Logistics The Supply Chain Consulting Group

Tesla S Gigafactory Supply Chain Vertical Integration Supply Chain 24 7

Teardown Tesla S Hardware Retrofits For Model 3 Ee Times Asia

Tesla Business Model And Strategic Analysis By Alec Furrier Medium

Drawing Lessons From Tesla S Supply Chain Issues

Tesla S Gigafactory Supply Chain Vertical Integration Supply Chain 24 7

What S Behind Tesla S Supply Chain Woes Supply Management

Tesla Business Model And Strategic Analysis By Alec Furrier Medium

Tesla S Revolutionary Supply Chain Supply Chain 24 7

Tesla Business Model And Strategic Analysis By Alec Furrier Medium

Tesla S Supply Chain Set For A Surge Article Automotive Logistics

Why Vertical Integration Made Tesla More Powerful By Behzad Benam Medium

Musk Says Tesla Prices Increasing Due To Supply Chain Pressure Automotive News Europe

Tesla Strategic Analysis Corporate Governance

Komentar

Posting Komentar